Barcode Validation & Verification - It's Black & White

Logopak is a GS1 Accredited Solution Provider. GS1 is an independent not-for-profit organisation who sets global standards to increase supply chain efficiency. This includes guidelines relating to the use of barcodes. Barcode validation and barcode verification are two important factors in ensuring best practice with barcodes, but the two terms are often misunderstood.

Barcode Validation refers to the process of ensuring the correct barcode information is applied to the correct product.

Barcode Verification is the measuring and grading of the quality of the barcode to the required ISO/ANSI standards.

Barcode Validation

Barcode validation refers to the quality control process of ensuring the correct barcode is applied to the product. Typically, barcode readers such as the Erwin SICK CLV610 is positioned on the production line reading point of sale, TUC and GS128 pallet labels.

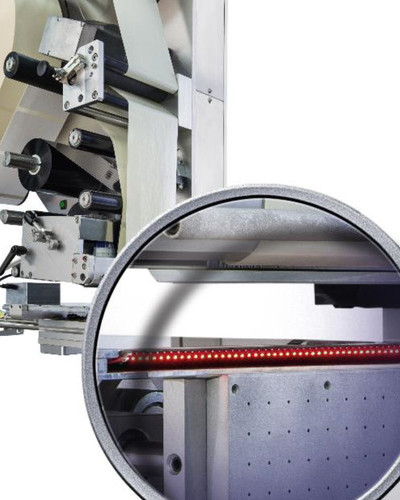

All Logopak labelling machines can be equipped with barcode validation scanners to ensure that any barcode label applied is readable and matches the current product. However, as the barcode readers cannot determine barcode quality, they cannot be classed as verifiers. The contents of the barcode is transmitted from each scanner to a control software such as Logopak’s iValidate. This software then compares the barcode data with the production data downloaded from the factories manufacturing information system.

Barcode Verification

More and more retailers are applying large penalties for non-compliant barcodes.

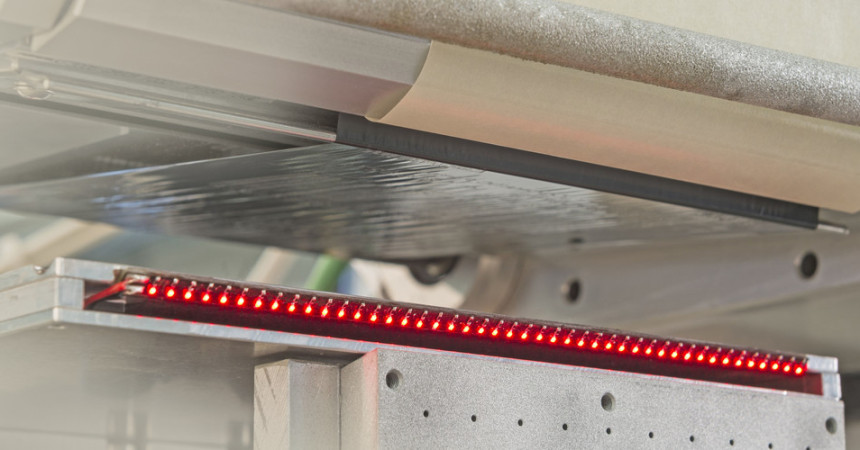

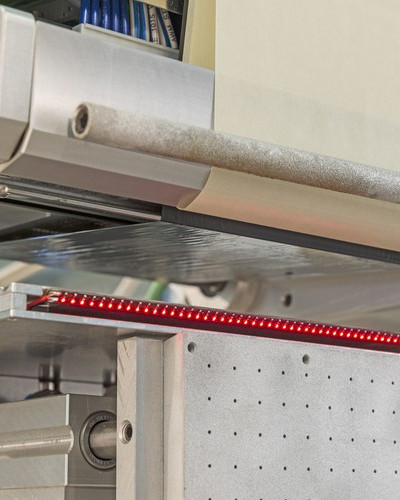

Verification is typically a manual process recording barcode quality every one to four hours. Retailers recommend the use of ISO compliant verifiers such as Axicon’s 7000 series. Camera-based verifiers control the surrounding light via LED’s, provide autocalibration the correct ISO aperture, and provide many other advantages over laser based systems.

A verifier checks criteria such as Symbol Contrast (SC), Minimum Reflectance (RMIN), Edge Contrast (EC), Modulation (Mod), Defects and Decodability.

GS1 says “Any verifier used to check the quality of GS1 barcodes should conform to the international standard ISO/IEC 15426-1 which will ensure that the codes are graded according to the standard ISO/IEC 15416."