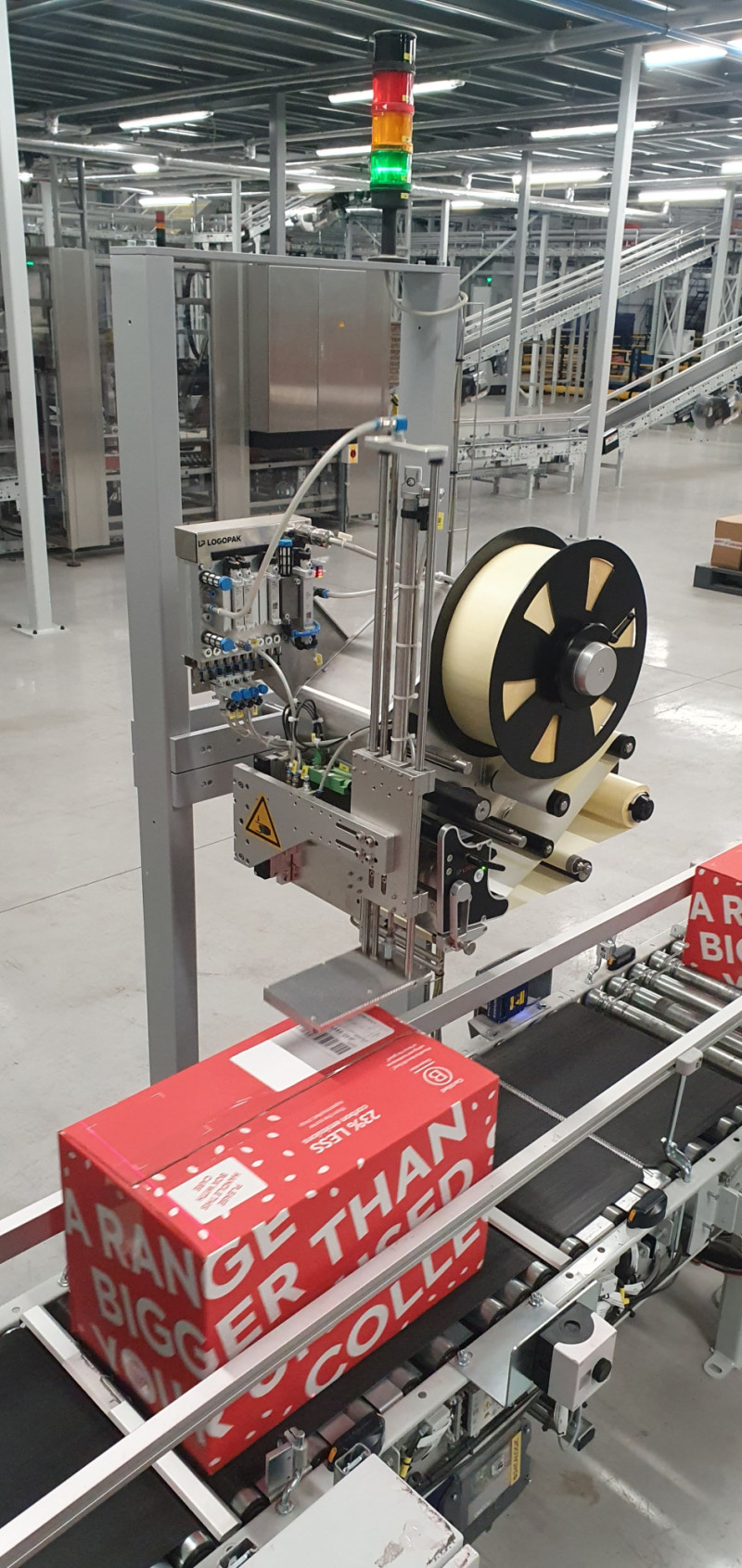

Automated Ecommerce packaging and labelling solutions

Any product entering the distribution / logistics supply chain requires identification in the form of a barcode shipping label. Predominantly the major carriers enforce the use of barcodes that conform to predefined individual company standards.

Logopak have experience of working with all the major carriers and have shipping label layouts approved and ready to implement for DPD, Parcel Force, Royal Mail and FedEx, Business Post, Amtrak, Home Delivery, UPS and more.

Solutions include standard shipping labels, document inserters for delivery note, invoice etc. to be inserted into box or bag, and over-shipping labels (OSL) which combine the shipping label and documents in one application.

The barcode symbology used can be Code 39, GS1 128, and Code 128 ideally printed onto a A6 sized shipping label that is applied to the side or top surface of a cardboard or bagged outer. The use of 2d barcodes is becoming more frequent due to the amount of data encrypted in such a small area compared to linear codes. One label per unit is acceptable if printed on demand, applied in ‘real-time’ and the barcode is displayed in ‘picket fence’ (vertical) orientation.

Ecommerce Carton Labelling

Ecommerce Auto-Bagging Machines

Document Insertion

Machine Features

What makes a good Ecommerce labeller?

- Precision light weight application. Blow on applicators (non-contact) to prevent any damage to the product during application especially if fragile products are being packed.

- Application speed. This can be as low as 10 ppm or as high as 50 ppm dependent of type of product. Any equipment supplied must be capable of achieving the desired speed with contingency should line speeds increase at a later date.

- Real time labelling. One-to-one labelling means there are no pre-printed labels on the label web or loop waiting to be applied. This means real time print data such as sequential number or real time clock data is absolutely accurate. No loop minimises label waste at product change over.

- Consumable stocks. This is a high volume production area, the downtime costs are high and therefore label roll capacity should be considered along with easy consumable changes from simple mechanical designs with as few threading rollers as possible.

- Reliability. The labelling solution is a critical part of the line process and must provide high degrees of efficiency, reliability, performance and accuracy.

- User Interface & Operation. A simplified User Interface ensures busy operatives can effectively set-up and replenish the labeller. Using standard label designs with pre-configured variable data, which can be recalled, collected, and uploaded locally or across the network. Large TDI touch-screens with intelligent fault finding diagnostics allow any faults to be easily recognised and resolved quickly.

- Barcode Validation / Verification. Barcode quality is key, on line validation in essence records every barcode printed and applied and is the control between the labeller and line PLC to trigger a stop should the barcode fail to be read or fall below the standard for scanning.

- Support of current 2d barcode symbologies.