Keg and cask labelling

Keg and cask labelling is essential for major brewers, who enforce the use of barcodes that conform to predefined individual company standards. Barcodes are key for traceability of product from brewery to public house and the return of the keg / cask. The label also provides the landlords with mandatory product description and best before date.

The barcode symbology used can be Code 39, GS1 128, and Code 128 ideally printed onto a 100mm x 70mm sized label that is applied to the top surface on the keg / cask. The label media is a unique material that can withstand the transport process and changing weather conditions, yet still be removed during the returns washing process.

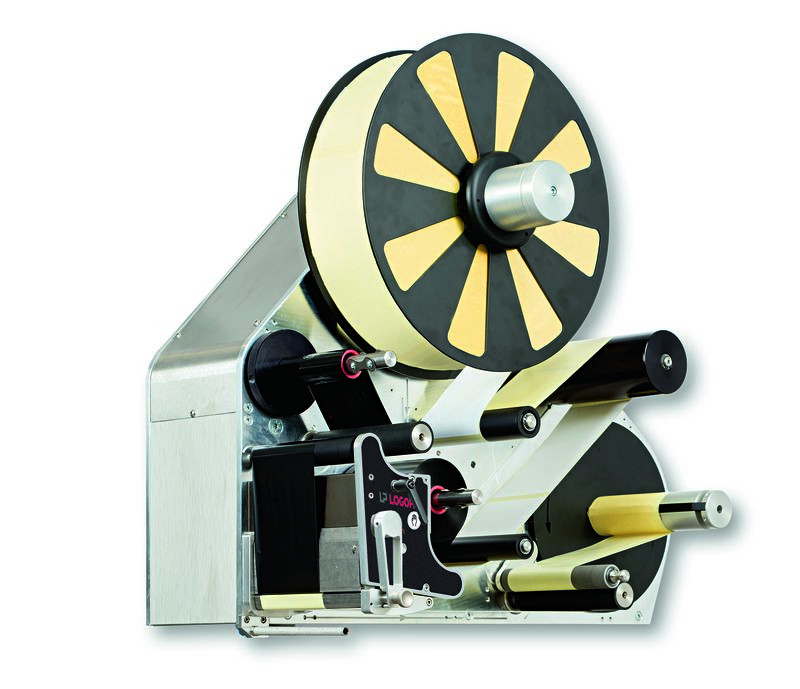

Depending on throughput speeds, Logopak offers two types of keg/cask labeller. All equipment is manufactured in-house and does not rely on any third party integration of hardware or software.

Body 1 Series Keg Labeller

Body 2 Series Keg Labeller

Machine Features

What makes a good keg/cask labeller?

To apply the perfect barcode label consideration for the following items is critical;

- Application. The keg / cask should be stopped on the conveyor for the label application. The label is applied by a telescope / tamp type applicator. The applicator telescope movement should be as short as possible and so the complete machine may have to be automatically raised or lowered to suit the size of the keg / cask. Specially designed soft applicator pads to prevent damage to the labeller and keg/cask are required.

- Real time labelling. One-to-one labelling means there are no pre-printed labels on the label web or loop waiting to be applied. This means real time print data such as sequential number or real time clock data is absolutely accurate. No loop minimises label waste at product change over.

- Consumable stocks. Modern fillers can run up to 1000 kegs/casks per hour and therefore a high speed applicator is required. In this high volume production, the downtime costs are high and therefore label roll capacity should be considered along with easy consumable changes from simple mechanical designs with as few threading rollers as possible.

- Application speed. This can be as low as 10 per minute or as high as 30 per minute dependent on the size/type of Keg/Cask. Any equipment supplied must be capable of achieving the desired speed with contingency should line speeds increase at a later date.

- Reliability. The labelling solution is a critical part of the line process and must provide high degrees of efficiency, reliability, performance and accuracy.

- User Interface & Operation. A simplified User Interface ensures busy operatives can effectively set-up and replenish the labeller. Using standard label designs with pre-configured variable data, which can be recalled, collected, and uploaded locally or across the network. Large TDI touch-screens with intelligent fault finding diagnostics allow any faults to be easily recognised and resolved quickly.

- Barcode Validation / Verification. Barcode quality is key, on line validation in essence records every barcode printed and applied and is the control between the labeller and line PLC to trigger a stop should the barcode fail to be read or fall below the standard for scanning.

- Enclosures. Keg/Cask labelling is installed at the end of most production lines in extremely demanding environments. Dust, dirt, water, steam, and beer are all possible elements that can cause machine failure if allowed to access the print head. In addition, extreme temperatures and high FLT activity can all impact on the reliability of the labeller. To overcome this, a pressurised and heated enclosure is essential.