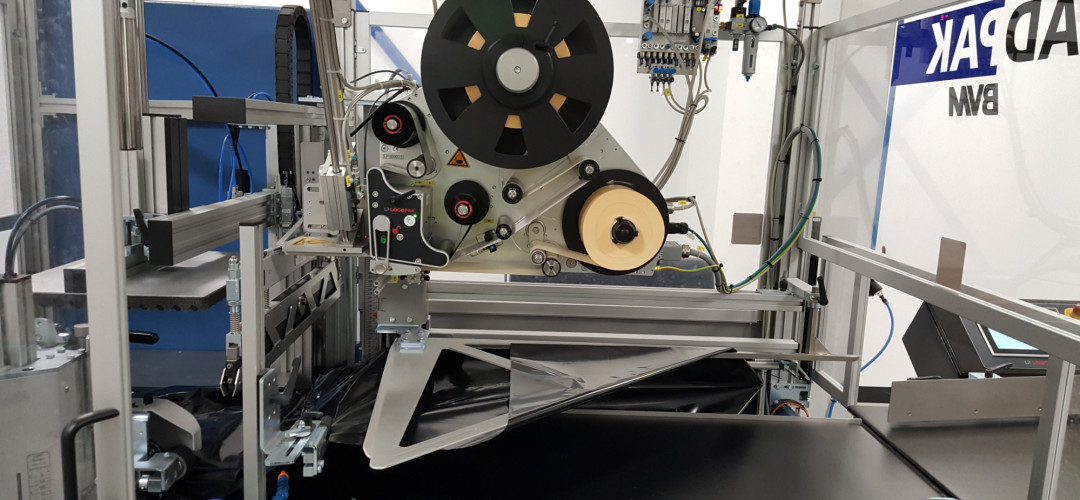

Logopak International Ltd have completed the installation of a fully automatic pallet labelling system for one of the UK’s largest hygiene and health product manufacturers. The system, installed at the customer’s manufacturing plant in Lancashire, consists of three cutting edge 850P2 pallet labellers, a pallet scanning array from partners SICK, a bespoke Logopak Synchro middleware package, plus an offline printer for labelling part pallets.

Pallets of finished product exit one of three production lines before being shuttled to one of the three automatic pallet wrappers. The pallet is stopped before the wrapper and the scanner array identifies the pallet’s contents, this information is relayed to the Synchro middleware which interfaces with the host ERP system. The pallet is stretch wrapped and then conveyed to one of the three automatic labelling stations. The Synchro middleware automatically generates the correct label data for each specific pallet. Two SSCC labels are then automatically applied to each pallet, without requiring any operator intervention.

Essity, Skelmersdale