Logopak provide the highest quality consumables to ensure perfect print and barcode readability.

The long-term readability of a label largely depends on the label material and quality. With more than 40 years of experience gained in Logopak‘s in-house test lab, our experts work on developing the right label for every need. Whether large or small, paper or plastic, standard or special adhesives, Logopak labels are ideal for a wide range of applications. We exclusively use high-quality and extremely resilient materials, which have been developed especially for use in industrial environments. What all Logopak labels have in common is their superior quality and maximum readability.

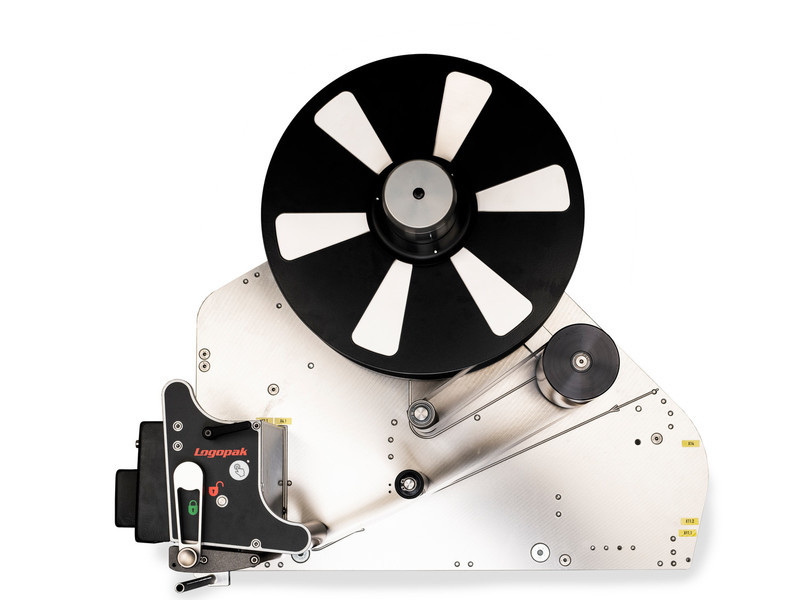

Labels and thermal transfer ribbons made by Logopak

Our Logopak labels and thermal transfer ribbons are perfectly designed for use with our labelling systems to guarantee efficient and trouble-free operation.

Your benefits at a glance

- Wide range of labels available for every application

- Outstanding print quality and readability

- Perfectly adapted for use with Logopak systems

- High machine availability for increased efficiency

- Fast delivery, available worldwide

- Sustainable product design through FSC and PEFC certification

- Greener: linerless labelling ensures environmentally friendly operation

All consumables are specifically designed to provide the best print quality and longevity of print.

Thermal

RFID

Security

Thermal Transfer Ribbons

Linerless

Sustainability in the supply chain

We are FSC® certified, this ensures that your business can purchase Logopak Consumables with the confidence and knowledge that your supply chain is benefiting from sustainable and ethically sourced wood-based materials.

Logopak consumables ensure your organisation:

- have complete traceability of your supply chain, from raw material stage to your site

- are leading the way in ethical Forestry sourcing

- are meeting and exceeding policy requirements

- are meeting your customers demands for FSC certified products

- are future-proof for changes in Forestry regulations. Logopak can advise on policy changes and ensure you’re always at the forefront of ethical sourcing

- is promoting environmentally appropriate, socially beneficial, and economically viable management of the world’s forests