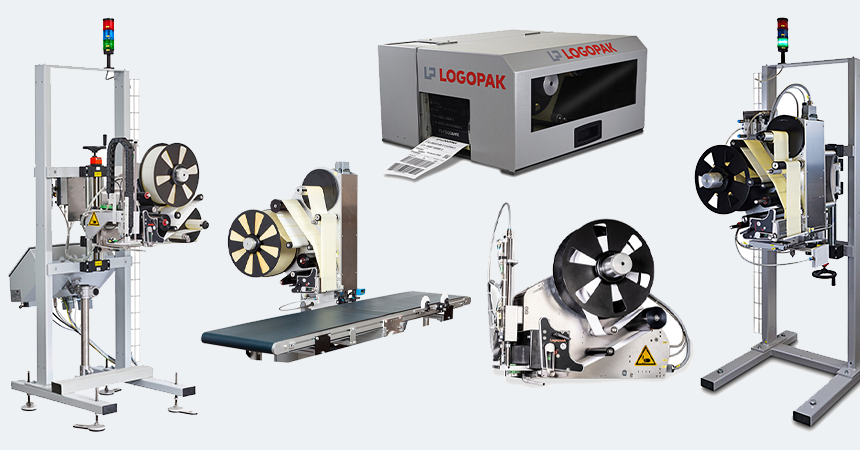

Case labelling

Suitable for outer case / pack labelling where global standard barcodes are applied to facilitate the supply chain and retailer requirements. A wide range of applicator types to accommodate any application to any face.

The outer case label contains either ITF14, EAN13 or GS1-128 barcode that identifies the product (GTIN) and can also contain BBE, batch and quantity information.

Depending on throughput speeds, Logopak offers three suitable case labellers. All equipment is manufactured in-house and does not rely on any third party integration of hardware or software.

200 Series Case Labeller

Industrial Desk Top Label Printer

The Logopak 200 series is a range of heavy duty off-line printers manufactured by Logopak with the same industrial DNA as Logopak automatic print & apply labellers.

They are manufactured using the same components that are used in the Logopak case and pallet labelling machines in order to give the end user full spare parts, print head and software compatibility.

Logopak 200 series printers are enclosed in 2mm thick steel housings to ensure more than adequate protection in even the most demanding locations – stainless steel enclosures are available as an option.

Learn more View Gallery

Standard Features:

- Front feed – labels dispensed with backing paper

- 4”, 6” & 8” Print head width options – for labels up to 210mm wide

- Print head resolution options – 203 or 300 dpi

- Label Gap Detection: Label gap-sensor

- Label Capacity: 150 m

- Ribbon Capacity: 300 m

- Control Unit: Controller VLP PL6

- Colours: RAL 9006 white aluminium (Stainless Steel option)

- Displays: Integrated 5" display VLP PL6

- Data Connection External: Ethernet 10/100 Mbs

Optional Features:

- Stainless Steel Housing

- Stainless steel support frame

- External label rewinder (bulk label printing)

- Internal backing paper rewinder (dispense labels without backing paper)

- Integrated cutter for automatically cutting labels after printing

- IO module for remote operation/monitoring and interfacing

- Integrated validation scanner

View less

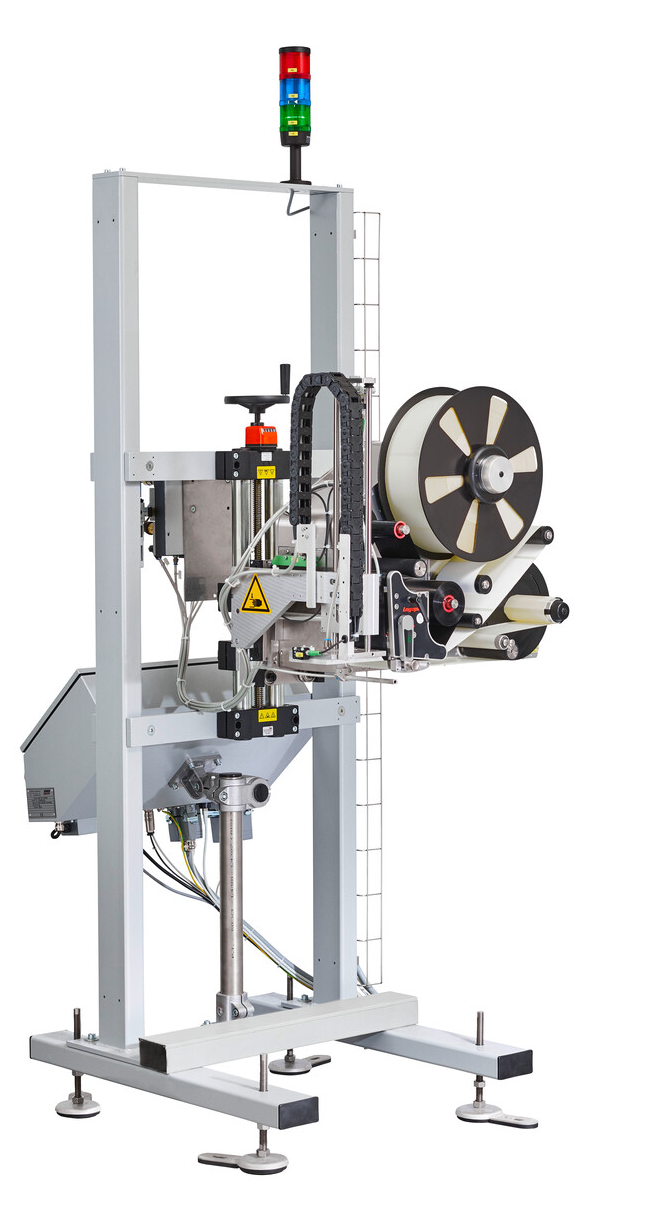

300 Series

Standard Range of Industrial Print & Apply Case Labelling Machines

The Logopak 300 series is a standard range of heavy duty print & apply labellers which can be specified for side, top or front label application. By restricting the available options available on the 300 range, we can offer an extremely high quality case labelling system at a very competitive price point.

Logopak labellers are manufactured using the same components that are used in all Logopak print & apply labelling machines and manual printers, this gives the end user full spare parts, print head and software compatibility.

A high speed option allows for labelling at up to 80 packs/minute for a single machine, and the long 600m label and ribbon capacity means reduced consumable changes and line stoppages.

Learn more View Gallery

Standard Features:

- Front, Side or Top label application

- 600m Label reel and ink ribbon capacity

- Thermal Transfer or Thermal Direct compatible

- Quick change print engine with options for 203 dpi or 300dpi

- Label widths up to 165mm

- 10” HMI for stand alone data handling (no additional PC required)

- Heavy duty steel support frame for superior labelling accuracy

- Open sided main drive and print engine for easy consumable changes

- Colours: RAL 9006 white aluminium (Stainless Steel option)

- Data Connection: Ethernet 10/100 Mbs

- IO module for full line integration

- Alarm pole with Error, Ready and Low consumables warning

Optional Features:

- Validation scanner

- Manual labelling height position adjustment

- Manual labelling side position adjustment/service slide

- Emergency stop circuit/button

- Perspex dust cover

View less

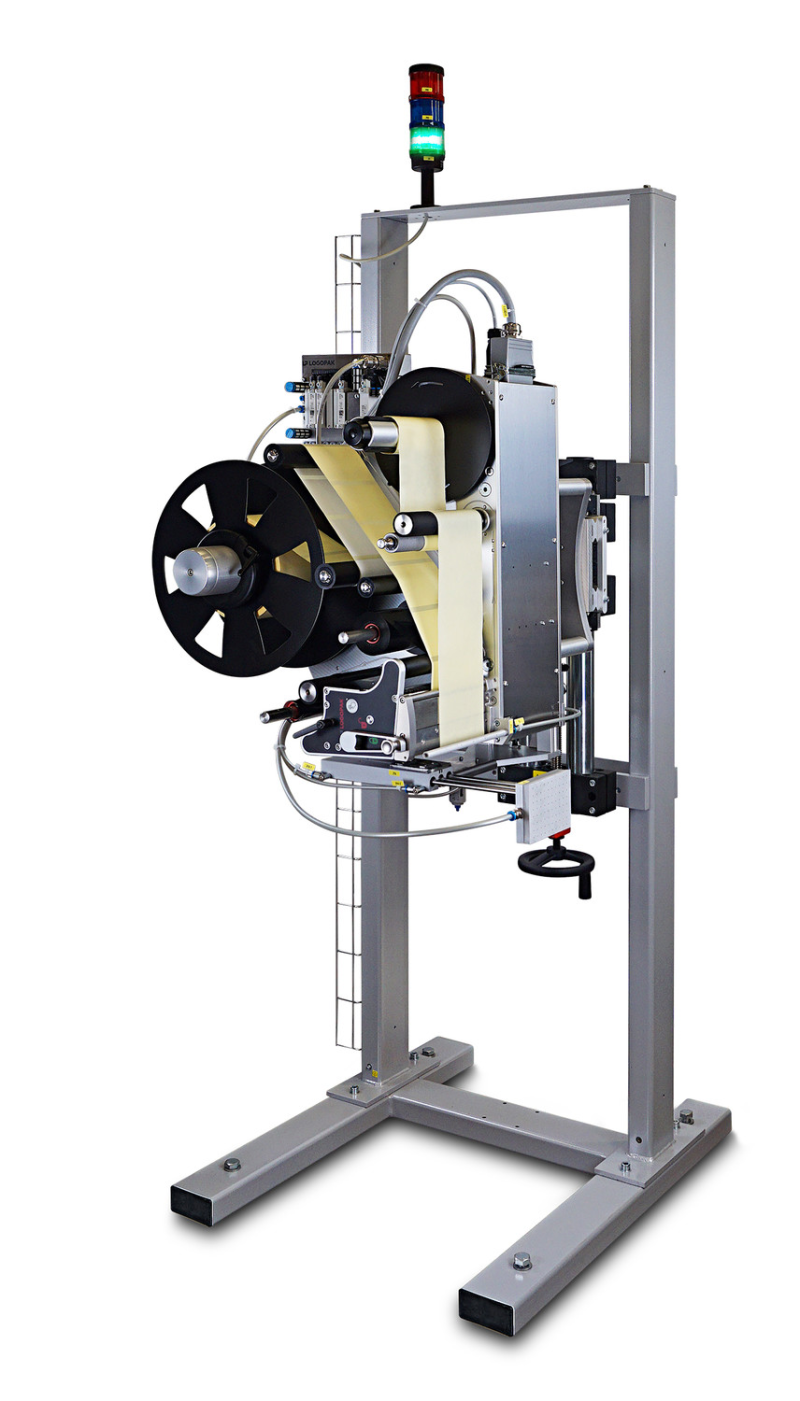

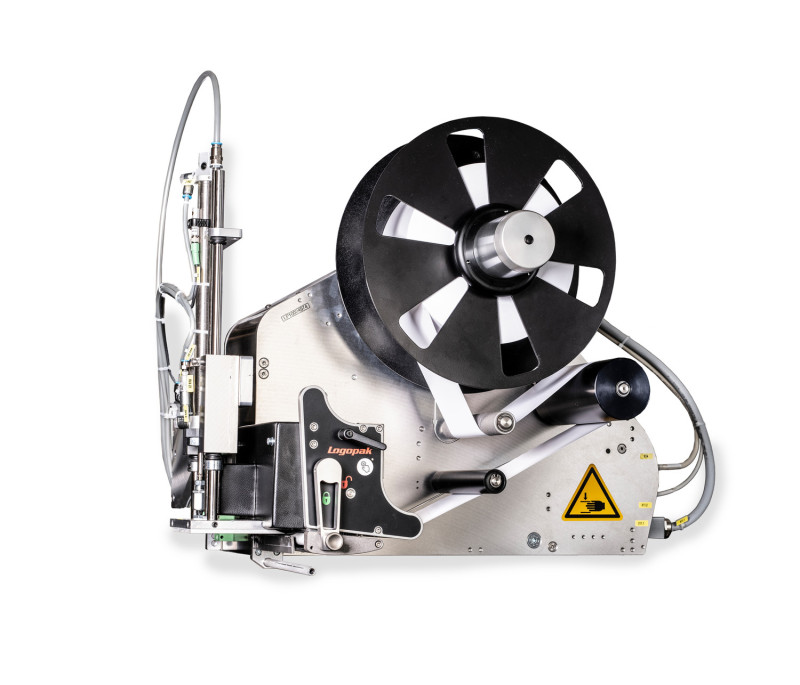

400 Series

Bespoke Range of Industrial Print & Apply Case Labelling Machines

The Logopak 400 series is a bespoke range of heavy duty print & apply labellers which can offer hundreds of build options. This allows a labelling system to be designed and built to perfectly suit the customer’s requirements.

Logopak labellers are manufactured using the same components that are used in all Logopak print & apply labelling machines and manual printers, this gives the end user full spare parts, print head and software compatibility.

Perfect for applications which require a non-standard solution, designed and built specifically for each customer.

A high speed option allows for labelling at up to 120 packs/minute for a single machine, and as with all of our case labelling systems, they can be configured as part of a Tandem/Tridem system for high speed, non-stop labelling.

Learn more View Gallery

Standard Features:

- Over 100 applicator configurations

- 600m Label reel and ink ribbon capacity

- Thermal Transfer or Thermal Direct compatible

- Quick change print engine with options for 203 dpi or 300dpi

- Label widths up to 165mm

- 10” HMI for stand alone data handling (no additional PC required)

- Network ready with full ZPL emulation – perfect for Ecommerce

- Heavy duty steel support frame for superior labelling accuracy

- Open sided main drive and print engine for easy consumable changes

- Colours: RAL 9006 white aluminium (Stainless Steel option)

- Data Connection: Ethernet 10/100 Mbs

- IO module for full line integration

- Alarm pole with Error, Ready and Low consumables warning

Optional Features:

- Linerless labelling option

- Validation scanner

- Manual labelling height position adjustment

- Manual labelling side position adjustment/service slide

- Emergency stop circuit/button

- RFID Enabled

- Full steel enclosure with trap door, lighting and heating

- Tandem/Tridem controller for high speed, non stop labelling

- Multiple label size handling

- Stainless steel options for control panel, frame and enclosure

- Bespoke software functionality

View less

400 Eco Linerless Series

Fully Automated Product Labelling with Less Waste

Conventional labelling with self-adhesive labels creates a huge amount of waste in the form of silicon release liner. Once the label is peeled off the liner, this material is destined for landfill or energy recovery. This is due to the material content of the liner, that proves difficult to recycle. Logopak have worked closely with one of the world’s largest paper manufacturers to offer a completely Linerless Labelling solution. Logopak’s Linerless technology now brings sustainable, eco-friendly labelling to the print and apply world, helping to reduce global waste and carbon emissions.

Logopak labellers are manufactured using the same components that are used in all Logopak print & apply labelling machines and manual printers, this gives the end user full spare parts, print head and software compatibility.

No longer requiring the liner paper has the additional benefit of longer label reel capacity, meaning fewer consumable changes and therefore line stoppages

Learn more

Standard Features:

- Side, Top and Pallet applicator configurations

- 1000m label reel capacity for minimum downtime

- Integrated low maintenance label cutter

- Thermal Direct label printing

- Variable label length handling

- Quick change print engine with high resolution 300dpi print head

- Label widths up to 165mm

- 10” HMI for stand alone data handling (no additional PC required)

- Network ready with full ZPL emulation – perfect for Ecommerce

- Heavy duty steel support frame for superior labelling accuracy

- Open sided main drive and print engine for easy consumable changes

- Colours: RAL 9006 white aluminium (Stainless Steel option)

- Data Connection: Ethernet 10/100 Mbs

- IO module for full line integration

- Alarm pole with Error, Ready and Low consumables warning

Optional Features:

- Validation scanner

- Manual labelling height position adjustment

- Manual labelling side position adjustment/service slide

- Emergency stop circuit/button

- Variable label length/width handling

- Stainless steel options for control panel, frame and enclosure

- Bespoke software functionality

View less

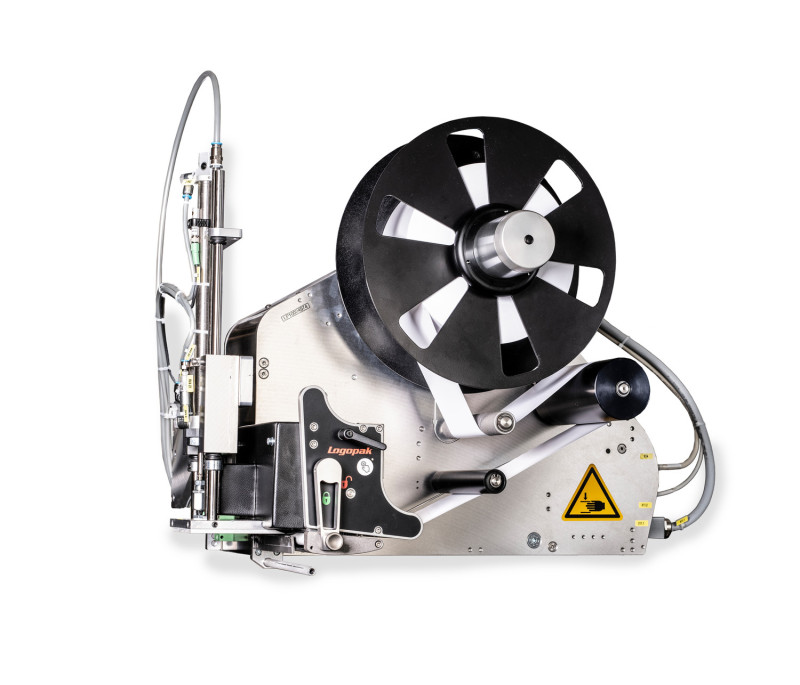

Bespoke Machinery

Logopak specialise in bespoke labelling solutions that are far from ‘standard’ in terms of application.

Logopak have designed and built bespoke labelling systems to apply labels to anything from a Montblanc fountain pen, to a Ford Transit van, from a 1 tonne roll of paper stock, to a set of golf clubs. Our team of technical experts will consider all projects and discuss the viability with the end user or OEM.

Logopak works closely with robotic manufacturers and integrators, and have installed numerous solutions incorporating robotic technology.

Learn more View Gallery

Standard Features:

- Over 100 applicator configurations

- 800m Label reel and ink ribbon capacity

- Thermal Transfer or Thermal Direct compatible

- Quick change print engine with options for 203 dpi or 300dpi

- Label widths up to 165mm

- 10” HMI for stand alone data handling (no additional PC required)

- Network ready with full ZPL emulation

- Heavy duty steel support frame for superior labelling accuracy

- Open sided main drive and print engine for easy consumable changes

- Colours: RAL 9006 white aluminium (Stainless Steel option)

- Data Connection: Ethernet 10/100 Mbs

- IO module for full line integration

- Alarm pole with Error, Ready and Low consumables warning

Optional Features:

- Validation scanner

- Manual labelling height position adjustment

- Manual labelling side position adjustment/service slide

- Emergency stop circuit/button

- RFID Enabled

- Full steel enclosure with trap door, lighting and heating

- Tandem/Tridem controller for high speed, non stop labelling

- Multiple label size handling

- Stainless steel options for control panel, frame and enclosure

- Bespoke software functionality

View less

Versatile range of applicators

Efficient consumable changes

Full supply chain compliance

Outstanding support service

Optimised for maximum productivity

Integrated barcode verification

What makes a perfect case labeller?

To apply the perfect barcode label consideration for the following items is critical;

- Application. Non contact blow on applicators offer the advantage of few moving parts and no parts in contact with the moving product. Ultra light weight applicators should be used if the label is required to be applied to a cardboard surface. Less weight = less wear.

- Real time labelling. One-to-one labelling means there are no pre-printed labels on the label web or loop waiting to be applied. This means real time print data such as sequential number or real time clock data is absolutely accurate. No loop minimises label waste at product change over.

- Consumable stocks. In a high volume production, the downtime costs are high and therefore label roll capacity should be considered along with easy consumable changes from simple mechanical designs with as few threading rollers as possible.

- Application speed. This can be as low as 10 ppm or as high as 100 ppm dependant of type of product. Any equipment supplied must be capable of achieving the desired speed with contingency should line speeds increase at a later date.

- Reliability. The labelling solution is a critical part of the line process and must provide high degrees of efficiency, reliability, performance and accuracy.

- User Interface & Operation. A simplified User Interface ensures busy operatives can effectively set-up and replenish the labeller. Using standard label designs with pre-configured variable data, which can be recalled, collected, and uploaded locally or across the network. Large TDI touch-screens with intelligent fault finding diagnostics allow any faults to be easily recognised and resolved quickly.

- Barcode Validation / Verification. Barcode quality is key, on line validation in essence records every barcode printed and applied and is the control between the labeller and line PLC to trigger a stop should the barcode fail to be read or fall below the standard for scanning.